Wind Turbine Blade Templates

Print off the diagram in the previous page making sure the scales are the correct size. The print out will probably cover more than one page so these will need to taped or glued together. Adjust the page height and width in the form and the landscape and portrait options on the printer to minimise the number of pages you need to join. Audio4fun Av Voice Changer Diamond 7 0 29 Crack Rhe here. The thin red tick marks at the corner of the pages must align, as should the axis and curves. I found it easiest to cut away the excess paper on one page to see the joint between the pages. The pages can be taped together and once joined it is easiest to glue the diagram to a piece of thicker card so it is stronger and can be easily traced around later.

Psp Cube Test Download. Demonstrate the working principle of a Wind Turbine, and make a working model of this device through free Wind turbine PowerPoint template for Engineering students. Wind Turbine Blade Design Joseph Rand The. That’s why our impressive Templates for PowerPoint product. Composite Materials for Wind Turbine Blades Wind.

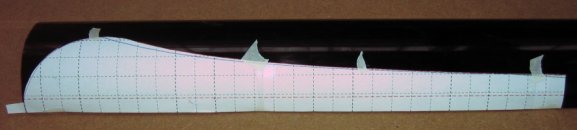

Polaroid Pdf 825 Reviews here. It is now possible to wrap the blade plan around the outside of the piece of PVC tube with the straight trailing edge along the axis and mark around the plan. I used semi circular PVC gutter which already had a straight finished edge.

If you are using a complete tube it would probably be easiest to cut it into sections down the length so the straight edge is already finished. Tape and small spring clamps are useful to hold the template. Where you have marked the holes for the hub bolts, drill these through the PVC tube. I cut the blades from the PVC using a small jig saw or by hand using a fret saw. They were cut slightly over size and then sanded back to the mark using a sanding drum mounted on a drill which left a clean finish.

The first blades I made I just sanded the leading and trailing edges round, like the blades in the photos. Since making the I've experimented with different blades to try to improve the performance. Sanding the concave side of the blade so the trailing edge is sharp and the leading edge has a slight round makes a measureable improvement in performace.

I am currently finishing a two year engineering course on wind turbine tech. We had a module on 3d desingn (solidworks) and for one of the assignments we designed a scaled down turbine blade, printed it and tested it in the college wind tunnel recording rpm. Amazingly i made an rpm reading of 80rpm on my turbine with which i was well pleased. This instructable will guide you on the designing of the blade using solidworks and i assume you have some basic experience if not on solidworks then some other 3d package. If not dont frete i have uploaded the screen shots i used in a.doc file along with the actual solidworks Part drawing.

Trace over the out line at each end of the blade with a vertical line. Next, we are going to divide the blade into 'stations' the reason will become clear later. I divided it up into 6 stations using the linear sketch pattern. Where the vertical lines cross the outline of the blade insert sketch points.